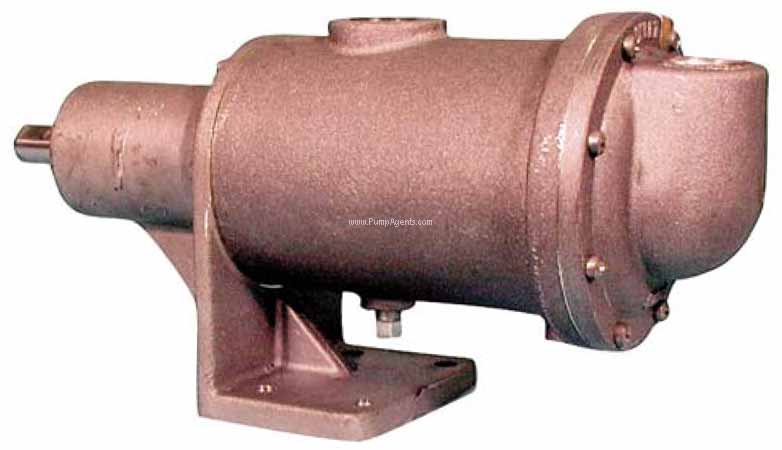

Oberdorfer # 121 Aluminum Helical Rotor Pump

Product Information :

The Oberdorfer 121 is an Aluminum Pedestal Helical Rotor Pump with Buna-N Stator, Buna-N Mechanical Seal, Stainless Steel Rotor, 3/4 inch FNPT by 3/4 inch FNPT Ports, replacement pump end only without a Motor. This pump is a helical rotor progressing cavity pump. Helical rotor pumps are a sturdy and robust category of positive displacement pumps, which comprise of a helix rubber stator and a helical rotor. The turning of the Stainless Steel helical shaped rotor within the stationary rubber stator creates a progressing cavity similar to a moving piston, and the liquid is thus displaced generating a pumping action. The rotor rotating inside the stator forms cavities via which media is pumped from suction to the discharge end of the pump. The rate of flow of the liquid is usually inversely proportionate to the pressure. The pump is relatively quiet as the rotor turns inside the resilient stator and thus generates little noise. Unlike piston pumping, extremely high pressure cannot be created because the stator is made of Buna N and is flexible. Because of this flexibe stator contaminated liquids can be handled. This pump is inherently self-priming, and the close fit of the rotor within the stator permits lifting of liquid on the suction side as high as 20 feet and does not require a foot valve. High starting torque motors are recommended in order to overcome the high starting friction of the stator, and usually the pump horsepower required is oversized to the operating horsepower required. This helical rotor design demands a single rotation - clockwise when facing the pump drive shaft. Pump rotation and "in" and "out" ports are indicated on the dimension diagrams on reverse side. The pump housing and mounting bracket is made from cast aluminum, the rotor is made from stainless steel with a hard chrome plate for improved wear properties. The stator is made from molded Buna N. The mechanical seal is a carbon and ceramic rotary face for positive sealing.

Features :

Applications

The corrosion resistant alloys used are compatible with common liquids including water, water solutions, oils and many commercial chemicals. Severe solvents are not compatible with the Buna and should not be pumped. Viscous liquids can be pumped, but at slower speeds. Samples of liquids, viscosity and recommended pump shaft R.P.M. are given on this page. Contaminated liquids can be pumped because of the flexible Buna stator. This pump can be used in a wide variety of applications including food processing, pumping abrasives or slurries, industrial applications, pharmaceuticals, wastewater processing and agricultural applications. This pump is nonclogging and can handle solid in suspension or media containing a high percentage of solids. This pump can operate at lower speeds and viscous or thick liquids must be pumped at slower speeds. Speed reduction from standard electric motor speed can be obtained by pulleys in the direct ratio of speed reduction desired large pulley on pump, small pulley on motor. Heavy liquids can be pumped at higher speeds but require more horsepower in direct amount to their specific gravity for example, a liquid with a specific gravity of 1.3 would require 1.3 times the original horsepower. A corkscrewlike action provides a pulse free flow where an accurate flow rate is determined by the rotor speed allowing for the helical rotor pump to also be used as a dosing pump.