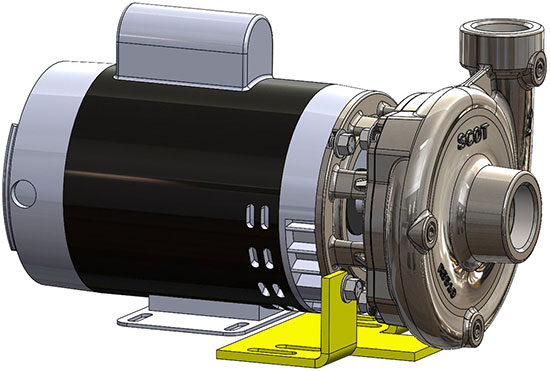

Scot Pump # 503S AS 1.5 x 1.25 Motorpump

Scot # 503S

Scot catalog # 503S, Motorpump 503S AS, All Stainless Steel end suction Centrifugal Pump and Motor unit, rated for a maximum flow of 120 GPM and 52 PSI, with Stainless Steel Construction, enclosed Stainless Steel Impeller, Mechanical shaft seal, 1-1/2 inch NPT Suction port, 1-1/4 inch NPT Discharge port, and is close coupled to an electric motor.

Price : $ 2272.00

Product Information :

The Scot Pump 503S is a Motorpump 503S AS, All Stainless Steel end suction Centrifugal Pump and Motor unit, rated for a maximum flow of 120 GPM and 52 PSI, with Stainless Steel Construction, enclosed Stainless Steel Impeller, Mechanical shaft seal, 1-1/2 inch NPT Suction port, 1-1/4 inch NPT Discharge port, and is close coupled to an electric motor. The Scot Pump 503S is a Motorpump 503S AS, All Stainless Steel end suction Centrifugal Pump and Motor unit, rated for a maximum flow of 120 GPM and 52 PSI, with Stainless Steel Construction, enclosed Stainless Steel Impeller, Mechanical shaft seal, 1-1/2 inch NPT Suction port, 1-1/4 inch NPT Discharge port, and is close coupled to an electric motor. This pump is a single-stage unit that is close-coupled to a NEMA-standard motor, and is built entirely of high-grade stainless steel for all wetted parts. All-stainless construction resists corrosion and contamination, making these pumps ideal for food & beverage, pharmaceuticals, marine, and corrosive-process industries needing dependable, low-maintenance performance. It is versatile in demanding environments, and this Stainless Steel Scot Pump excels in chemical handling, food-grade and potable water systems, seawater and wastewater applications, and industrial processing. It's close-coupled pump and motor design ensures precision alignment, compact footprint, quieter operation, and simplified installation.

Features :

Parts and Accessories for Scot model 503S

Applications

The Scot 503S Stainless Steel centrifugal motorpump is ideal for applications that demand superior corrosion resistance, hygienic operation, or chemical compatibility. In the pharmaceutical and cosmetic sectors, it's smooth, nonreactive surfaces help maintain fluid purity and prevent contamination. This pump is also widely applied in chemical processing, fertilizer transfer, and marine environments, where exposure to aggressive chemicals, saltwater, or brine would corrode standard iron or bronze pumps. Furthermore, it supports industrial cooling systems, highpurity rinse cycles, and reverseosmosis or deionized water loops. The use of 304 or 316 stainless steel combined with highquality mechanical seals ensures longterm durability in challenging environments, making this pump a trusted solution across sanitary, corrosive, and highperformance fluid systems.