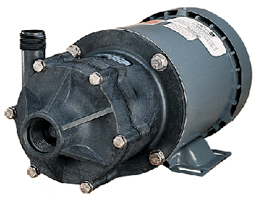

Little Giant # 586604 TE-6-MD-HC Magnetic Drive Centrifugal Pump 1/2 HP

Little Giant # 586604

Little Giant catalog # 586604, TE-6-MD-HC Magnetic Drive Centrifugal Pump, for Non-Submersible In-line Use, rated for 2280 GPH gallons per hour at 1 foot of head open flow. Motor is 1/2 Horsepower, 115/230 Volts, Single Phase, TEFC (Totally Enclosed Fan Cooled). Motor has a 6 foot cord. Inlet Port is 1 inch FNPT, Discharge Port is 3/4 inch MNPT.

Price : $ 1198.50

Product Information :

The Little Giant 586604 is a TE-6-MD-HC Magnetic Drive Centrifugal Pump, for Non-Submersible In-line Use, rated for 2280 GPH gallons per hour at 1 foot of head open flow, with a 1 inch FNPT inlet port by 3/4 inch MNPT outlet port, coupled to a 1/2 Horsepower, 115/230 Volts, single phase, TEFC (Totally Enclosed Fan Cooled) Motor. The Little Giant MD-HC series features leakproof, seal-less magnetic drives and are designed for in-line, nonsubmersible use. Volute, magnet housing and impeller are glass-filled Ryton for excellent chemical resistance. Ceramic shaft and thrust washers are 99.5% pure alumina for excellent wear and reliable service. Pumping heads are easily rotated, cleaned or serviced. Spindle shaft is supported at both ends to prevent impeller damage during start-up and stop of pump. The pump's volute and backplate are made from glass-filled Ryton; its impeller, glass-filler Ryton with carbon bushing; its shaft and thrust washers, ceramic; and its O-Ring, Viton. This pump uses ball bearings, a conduit box, and a thermally protected, totally enclosed, fan-cooled, split phase motor. It has a run-dry capability of up to 8 hours, and a specific gravity up to 1.1. It can pump fluids with a maximum temperature of 180 F, and can operate in a maximum ambient air temperature of 77 F

WEIGHT : The Little Giant 586604 weighs 29 Lbs.

Features :

Applications

There are many applications that the Little Giant 586604 are used in. Typical applications for this pump include Circulation of highly corrosive acids, alkalis, solvents, brine, plating solutions, sterile solutions, and other highly corrosive chemicals and solutions that are compatible with the pump's material of construction.

This Little Giant pump is delivered to you completely preassembled and pretested from the factory. It is ready for immediate use. The pump may be installed in any position. It may be mounted vertically with the pump head down. Proper plumbing connections should be made. See specification table to determine what size intake and discharge The pump has. Use a thread sealer on all pipe connections and hand tighten only. Note A roll of PTFE pipe seal tape is supplied. Do not use a wrench to tighten the connections. Excessive force may damage the plastic part. Make sure the wing nuts are tight before operating the pump. Check local electrical, building codes and plumbing codes before installing. Installation must be in accordance with all local and state or provincial regulations, as well as the most recent National Electrical Code NEC. The motor nameplate lists the electrical data and the pump should be wired per the diagram shown on the motor nameplate or under the wiring compartment cover. Three phase units do not have a thermal protective device integral with the motor that will protect the motor from overheating due to overcurrent or failuretostart conditions. A separate overcurrent protection device is required for overload conditions and/or shortcircuit/ground fault conditions. Three phase units must be wired into a separate control panel for operation. Refer to the instructions supplied with the control panel for installation and additional safety procedures. If control panel instructions are not available, contact the control panel manufacturer or supplier. See Table 1. These pumps are not submersible. Operate the pumps only in the inline mode. Do not put the units in liquid. Pump should be installed in a dry area and protected from splash. These pumps are not self priming. IMPORTANT These pumps must be installed so that the pump head volute is flooded before starting. That is, the inlet of the pump must be below the level of the surface of the liquid being pumped. See Figure 1. Do not restrict the intake side of the pump. Connections on the intake side should not be of smaller inside diameter pipe or tubing or hose than the intake inside diameter of the intake thread designation. If reduced flow is required restrict the discharge side. Installing a valve or other type of restriction device on the discharge side is the proper method for reducing flow from the pump. When using a valve the pump can be throttled to provide various flow rates and pressures without harming the motor or the pump parts