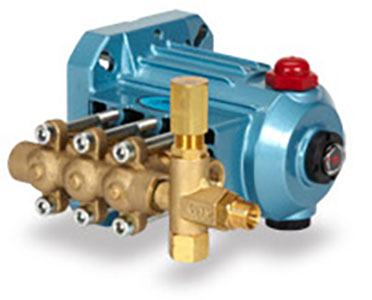

Cat Pump # 2SF22ES Plunger Pump

Cat # 2SF22ES

Cat catalog # 2SF22ES, Plunger Pump, pump end only, with Brass construction, 3/8 inch NPT(F) Inlet port x 3/8 inch NPT(M) Discharge port, and is rated for up to 2.2 GPM, and 2000 PSI at maximum shaft speed of 3450 RPM.

Price : $ 640.19

Product Information :

The Cat Pump 2SF22ES is a Plunger Pump, pump end only, with Brass construction, 3/8 inch NPT(F) Inlet port x 3/8 inch NPT(M) Discharge port, and is rated for up to 2.2 GPM, and 2000 PSI at maximum shaft speed of 3450 RPM. This triplex (three plunger rods) positive displacement, reciprocating plunger pump is constructed with brass manifolds, 304 stainless steel valve assemblies, solid ceramic plungers and standard NBR (Buna-N) seals and O-rings. 2SF Series pumps are hollow-shafted and designed to bolt directly to either a C-face electric motor or gas engine, depending on the model, providing an easy, compact installation. In this SF series pump, both the inlet and discharge valves are spring-loaded closed and hydraulically opened, similar to plunger pumps, however, they have a flow-through ceramic plunger design. The continuous forward flow characteristic of piston pumps is utilized in conjunction with the packing design of the plunger pumps. These features give SF pumps both strong suction capabilities and higher pressure performances. IMPORTANT : All high-pressure systems require a primary pressure regulating device (e. g. regulator, unloader) and a secondary pressure relief device (e. g. pop-off valve, relief valve). Failure to install such relief devices could result in personal injury or damage to pump or property.

Features :

Parts and Accessories for Cat model 2SF22ES

Applications

Cat Plunger Pumps are engineered for highpressure performance in rigorous environments. These triplex positive displacement pumps deliver consistent pressure and flow, making them ideal for applications such as industrial cleaning, hydrostatic testing, and pipeline flushing. In oil and gas operations, they are commonly used for wellhead maintenance and chemical injection. Their compatibility with aggressive fluids and their ability to operate under extreme duty cycles make them a top choice for reverse osmosis systems, misting and fogging, and cooling applications in industrial processes.