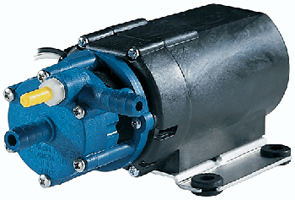

Little Giant # 532012 35-OM Pump 1/11 HP

Little Giant # 532012

Little Giant catalog # 532012, 35-OM High Pressure Pump, non-submersible, rated for 170 GPH gallons per hour at 1 foot of head open flow. Motor is 1/11 Horsepower, 230 Volts, Single Phase. Motor has 24 inch leads. Inlet Port is 3/8 inch barbed, Discharge Port is 3/8 inch barbed.

Price : $ 256.50

Product Information :

The Little Giant 532012 is a 35-OM high pressure Pump, non-submersible, rated for 170 GPH gallons per hour at 1 foot of head open flow, with 3/8 inch barbed inlet port by 3/8 inch barbed outlet port, coupled to a 1/11 Horsepower, 230 Volt, single phase Motor that has 24 inch leads. This is a Non-submersible, high pressure pump for carpet cleaners, dispenser-displays and pressure-washer applications. Nylon pump head, Ryton impeller, 3/8" barbed O.D. intake and discharge connections. 1/4" barbed O.D. by-pass adapter included. Double-insulated motor (non-replaceable brushes last 500 to 1,000 hours) with 94-V-O thermoplastic housing. This pump uses a 1/11 HP motor, a 3/8 inch OD intake, and a 3/8 inch OD discharge. It can pump liquids with a maximum temperature of 120 F. The pump's housing and volute are made from nylon; its impeller, Ryton; nd its shaft seal, carbon or ceramic. This pump can handle 35 PSI of pressure, and is designed to be used in high pressure applications. It uses a nylon pump head, a Ryton impeller, a carbon/ceramic shaft seal, a 3/8 inch barbed intake and discharge, a 1/4 inch barbed by-pass adapter, and a double-insulated motor

WEIGHT : The Little Giant 532012 weighs 2.67 Lbs.

Features :

Applications

There are many applications that the Little Giant 532012 are used in. Typical applications for this pump include Nonsubmersible, high pressure, carpet cleaning, dispenser displays, and pressure washers.

The pump is delivered completely preassembled and pretested from the factory. It is ready for immediate use. The pump may be installed in any position. It may be mounted vertically with the pump head down. Proper plumbing connections should be made, see specifications. Motor nameplate lists all electrical data. Make sure the pump is connected to proper voltage before operating. Do not allow pump to run dry. These pumps are not submersible, operate the pumps only in the inline mode. Do not put the units in liquid. Pump should be installed in a dry area and protected from splash. These pumps are not self priming models; they must be installed so that the pump head volute is flooded at the time the pump is to be started. That is, the inlet of the pump must be below the level of the surface of the liquid being pumped Figure 1. Do not restrict the intake side of the pump. Connections on the intake side should not be of smaller inside diameter hose than the intake inside diameter. If reduced flow is required, restrict the discharge side. Installing a valve or other type of restriction device on the discharge side is the proper method for reducing flow from the pump. When using a valve, the pump can be throttled to provide various flow rates and pressures without harming the motor or the pump parts. Use the bypass port for applications that have priming problems, closed discharge or dead head. Under dead head conditions, without bypass, the high RPM of the impeller approximately 9000 RPM will cause liquid to heat and vaporize. This results in the pump running dry and seal failure